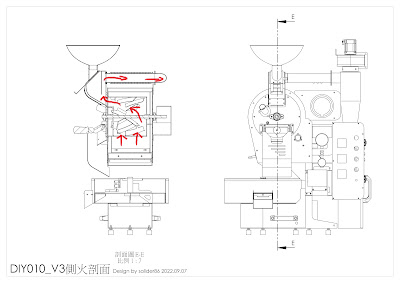

所謂側火建構的加熱系統。

對流熱高的烘焙系統,仰賴保溫性強的烘焙室,烘焙桶的厚度也需要對應,過厚或過薄都會影響烘豆者的操控性,側火是我目前設計的烘豆機中較注重操控性的烘焙系統,從烘豆者能操作的範圍為前提製作。

--------------------------------------------------------------------------------------------------------------------------

The Heating System of the so-called Side Heating(Fire) Construction

December 04, 2020

The side heating system, is basically with a high proportion ratio of convective heat (hot air).

1. The roasting drum which been set further away from the flame:

When using the high-efficiency of the pipe burner(tube burner) which also heats up the air extremely, thus to avoids the flame directly touching the roasting drum. Due to the ratio of convective current is greatly increased, the advantage is that the heat control is more intuitive, expansion of the beans are evidently and the color is lighter.

2. The burning of chuff is reduced:

The direction where the flame enters is same as rotation of the roasting drum, there are some chuff dropped at the front end of the semi convection roasting drum and the chance to be burn by the flame is less. However, the beans in the conduction roasting drum are concentrate on the far side of the flame, the chuff directly dropped by the conduction roasting drum also less burned. But when roasting in large quantities, the chuff collection tray must be taken out and clean regularly.

3. The wide range use of variable frequency damper:

This side heating roaster adopts a fan with a DC variable frequency motor, which can provide a stable speed to correspond to the pressure of the air extraction. The air extraction system:

Set the suction value → Detect the suction pressure in the duct → Transmit the pressure value → PID calculation → Adjust the motor speed → Reach the suction value

Repeat the above adjustments, and the suction pressure will be kept within a range as close as possible. This is due to the unstable air flow caused by the rotation of roasting drum that stirring the green beans, the differential pressure gauge to assist the roaster determine the value.

The diagram below is a cross-sectional view of the side-heated coffee bean roaster, illustrate the path of cold air entering the roasting chamber after being heated by the fire row:

The diagram below is a cross-sectional view of the semi-convection, air movement path which enters from the back of the roasting drum to the top through the air duct.

The diagram below is a conduction roasting drum, air enters through the holes on the surface of the roasting drum and moves to the upper air duct.

The roasting system with high convection heat relies on the roasting chamber with strong heat preservation. The thickness of the roasting drum also needs to be considered in corresponding towards the process, as too thick or too thin will affect the maneuverability of the roaster. The side heating roaster is my current design of roasting machines that need to pay more attention on maneuverability, this roasting system is made based on the roaster who is capable to manipulate.

※Thanks George for the English translation.

留言